Strategies towards a circular sports climbing market.

Because we must take responsibility

Sports climbing. 1 of the fastest growing sports in the world. It fits the trend of the uprise of “commercial sports”. Being Olympic for the first time in Tokio (and will be again in Paris 2024 and Los Angeles 2028). The low-level access to practice the sport with anyone, despite the difference in the level of the practitioners. The easy adrenaline shot, the attractive community. Possibility to take the sports to the outdoor. All factors which contribute to the rapidly growth of the sport. But with growth come challenges. Challenges that look paradoxical with the values of the sports climbing community and market. We must take responsibility.

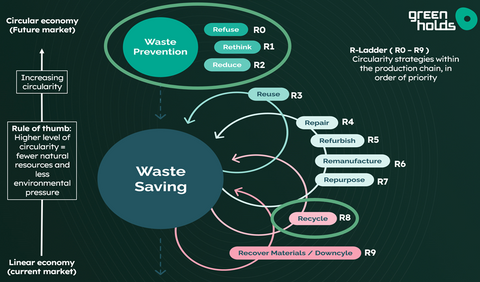

The current market is linear in every aspect, and therefore not sustainable. We need to shift to a circular market. This is exactly what we stand for with Greenholds. But how can we achieve that? In this blog, we explain by using the R-ladder as a framework, how we are going to accomplish our mission, our purpose. Together with the market!

What is the R-Ladder?

The R-Ladder is a valuable tool that provides insight into which circularity strategies provide a lower footprint. Circularity strategies that are higher on the ladder save natural resources. These strategies are the ingredients, which allow us to take responsibility and move towards a circular market.

Impact

How can we make the biggest impact? This was our point of departure 5 years ago. With our focus on climbing holds we took the upper 3 strategies in account in our circular design thinking. Refuse, Rethink and Reduce! On top of that we wanted to be our holds to be 100% recyclable. So R0 -R1 -R2 and R8 was the name of our game!

Refusing (R0) Thermosets

Starting with the biggest and most disruptive aspect of the Greenholds climbing holds. The Refusing (R0) of thermosets! The PU and PE holds produced by nowadays market are thermosets. Even the “ecological” versions, or the ones with natural additions remain thermosets. According to the dictionary the definition of a thermoset: “a material, esp a synthetic plastic or resin, that hardens permanently after one application of heat and pressure”. In other words, at the end of life it will be garbage. Bear in mind that we produce over 60 million holds each year globally… So, this is the challenge we face. The numbers will go up. Our solution we are willing to share; using a thermoplastic to produce climbing holds. The definition of a thermoplastic: “types of plastic which become soft when they are heated and hard when they cool down.” Our holds are made of Polyamide (Nylon). In other words, our holds can be recycled at the end of life. No garbage. It gets even better. We even use Polyamide out of waste streams. So, no virgin material is used to produce our climbing holds.

Rethink (R1) the way of producing

Injection moulding is the way we produce our holds. 5 years of R&D with 10 different entities and over 140 students resulted in a clever metal mould. No silicon moulds are used! With this 1 mould we potentially can produce more than 100 shapes! With the use of metal moulds, the biggest challenge was getting the surface structure right. We managed to create roughness for the perfect grip, with a different feel. Continuing insights while our research keeps progressing, result in even more cost-efficient production, which will reduce the initial investments on the long term. A radical rethinking of the production method.

Reduce (R2) the use of materials

Our holds are circular designed and engineered. This means that despite the use of little material, our holds are ultra strong. Our hollow backed holds are accurately calculated with thin rib constructions for strength. This results in minimum use of material. During production the spur is removed and thrown back into the machine. No waste is generated during the production of our holds. Next to that our holds are long lasting. The surface structure is extremely wear resistant which results in a long life for our holds. Long life means less producing holds which results in reducing the use of materials.

Recycling (R8) Greenholds

Not highest on the ladder, but maybe our biggest value proposition! Our holds are the only holds on the world that are 100% recyclable. The design is a single material product (no washers or iron wire inside), which ensures that we can "simply" throw our holds into the shredder, melt the granulate and produce new holds again. The biggest value is that towards the future we can work toward a circular business model. With expanding our product portfolio on short term, we will work towards a “Product as a Service” business model on the long term. Good to know for the market is that we will maintain a private label strategy. This means that we are very open for collaborations with other brands to produce for them using the Greenholds materials and production method.

Achieving more together

With our private label strategy, we are shouting out to the world we want to collaborate! We simply can’t proceed the way we are going now. So, this blog is also an invite to everyone out there who wants to contribute towards a more sustainable planet and a more sustainable climbing sport!